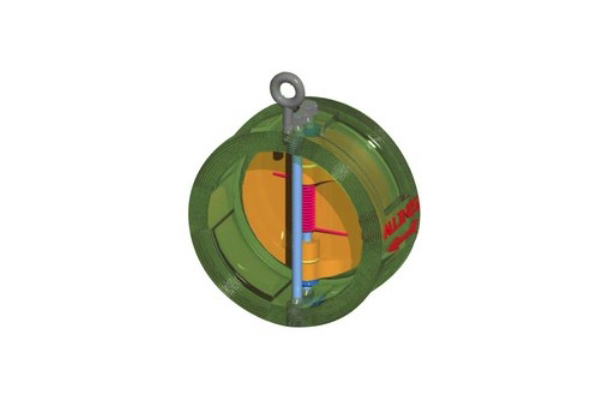

Dual Plate Check Valve

Design Features:

• “Dual Plate Check Valve” is an all purpose Check Valve (NRV). The Valves are designed to API 594 and comply with API 598 Valves inspection & testing standard. This design has distinct advantages over conventional Swing Check Valve or any single disc design

• Structurally sound

• Hydraulically engineered

• Stronger, Lighter and Smaller size. it weights about 1/5th weight of conventional valve

• Flexible installation: Can be installed in horizontal or vertical line without any special pipe support.

• Salient valve – Water hammer & Slamming almost eliminated

• Low pressure Drop hence lover energy loss

• Size range : - 2” (50 MM) to 24” (600 MM) N.B.

• Pressure rating : - ANSI 125,150,250,300 & PN 25

Construction:

• Body & Plates : C.I./C.S./S.S./ALLOY STEEL/AL. Bronze to A-216 Gr. WCB, CF8, CF8M, LCB, B.S.1400 AB 2 OR any other alloy as per Buyer’s specifications

• Hinge & Stop Pin : Stainless Steel or Bayer’s specification

• Pin retainer : C.S./stainless steel or Bayer’s specification

• Springs : S.S.-304 / S.S. 316 / Inconnel

• Seal : Buna –N, Viton –A or metal to Metal

• End Facing : Plain Face, Raised Face or Ring Joint Facing

Technical Data:

• Dimensions as per API-594 expect for ANSI-125 series

• Hub diameter (A) can be supply to Suit Flange Sizes as per BS / ANSI / DIN/ JIS or any other standard as per Bayer’s Specifications.

• The Valves are also available with Flanged Ends with Wafer Design as well as is long pattern having face to face Dimensions as per BS-1868 / API 6D / ANSI B-16.10

Applications:

• Water

• Air

• Oil

• Gas

• Steam or any other fluid