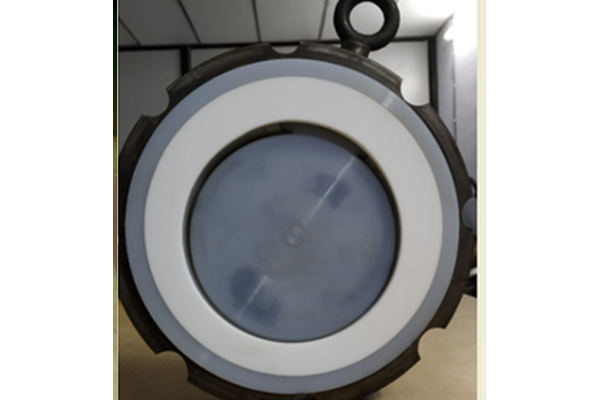

PTFE Lined Wafer Check Valve

Salient Features

• Meet design specification as per B 16.34 / API 6D.

• Testing Standard as per Mfg. Std.

• Lining Standard as per ASTM F 1545

• The construction of wafer design valves allows them to be sandwiched between flanged section of the pipe lines.

• A High Integrity PFA moulded wafer check valves body, with a fully encapsulated one piece disc / hinge assembly ensuring maintenance free service.

• A valve that is designed to allow the fluid to flow in a given direction but closes to prevent. back flow. Check valves are usually self acting.

• PFA Lined wafer swing check valves are ideal for use in highly corrosive applications.

• These valves can be used in horizontal and vertical installations due to the special design with a face PTFE cover encapsulated body with both side. PTFE Cover supports against the disc to achieve a seal : Open / Close positions within pipeline.

• The disc design can swing freely within piping system interference with the inside diameter of the connecting pipe lines allows to suit both ASME 150# & DIN PN -10 / PN -16 systems.

Technical Data

• Size Range : 1”NB to 12”NB

• Pressure Range : 0 to 6 Bar

• Temperature Range : -60°C to +200°C

• Body Material : S.G. Iron (NOD CI) / WCB / CF8 / CF8M / CD4MCu + PTFE Lined

• Lining Material : FEP / PFA / PVDF / Ceramic / Antistatic PFA Lining

• Spark Test : 100% Inspected at 15 KVA

Applications

• Industrial Inorganic Chemicals

• Industrial Organic Chemicals

• Plant protective agent production

• Alkali’s & Chlorine

• Detergent production

• Water treatment

• Bromine Production

• Sulfur recovery

• Nitrogenous & Phosphorus Fertilizers

• Food Processing

• Pharmaceutical Preparation

• Sugar Industries

• Petroleum Refining