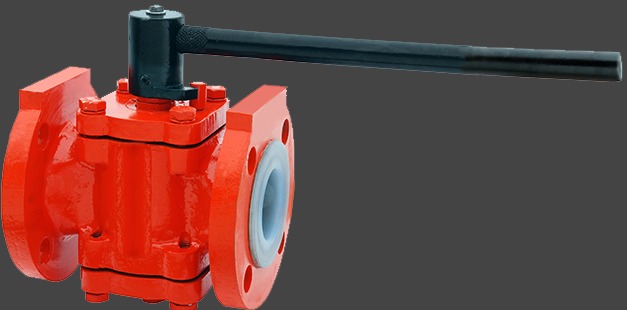

PTFE Lined Plug Valve

Salient Features

• Meet design specification as per BS 5353 / B 16.34 / Flange dimensions as per B 16.5

• Testing Standard as per BS - EN 12266 - 1 / DIN – EN – 588–1

• Lining Standard as per ASTM F 1545

• A one piece top entry PFA Lined Encapsulated taper plug design provides maximum corrosion resistance.

• The PFA body liner cover all wetted surface in the body and the plug extends are sufficiently cover as well.

• The solid taper anchored PFA Plug liner material ensures a strong adhesion.

• “T” – Slots matching will be a tight and perfect fit of the liner and additional support during vacuum service

• The Interface between the tapered outer plug and the tapered linear body provides a 360? primary sealing area.

• There are no cavities where flow media can accumulate or contaminate.

• In additional to large seating area the valve is fully bi-directional and the seal is totally independent of pressure.

• Large sealing surface from a port to port bubble – tight shut-off.

• A static eliminator which provides a positive electrical ground between the body and plug.

• A Secondary dynamic self adjusting PTFE “V” Rings prevents stem leakage.

• In line adjustment:- when seal presence adjustment is required due to sleeve wear, slight rotation of cover adjustment bolts. Pushes the plug downwards thereby providing extra sealing pressure / extra service life.

• Flow characteristics for control application.

• Full Port are assures low pressure drop and high flow characteristics.

Optional Features

• Locking arrangement available on request

• Extended stem design available on request

• Gear box / Pneumatic or Electric Actuator available on request

Technical Data

• Size Range : 1”NB to 4”NB

• Pressure Range : 0 to 6 Bar

• Temperature Range : -60 °C to +200 °C

• Vacuum resistance : Full (Vacuum up to 16 Bar)

• Tightness : BS-EN-12266-1

• Leakage rate : D, Test Media: Gas

• Leakage Class : as per Class VI shut off.

• Body Material : S.G. Iron (NOD CI) / WCB / CF8 / CF8M / CD4MCu + PTFE Lined

• Lining Material : FEP / PFA / PVDF / Ceramic / Antistatic PFA Lining

• Spark Test : Thick liner 100% Inspected at 15 KVA

Applications

• Industrial Inorganic Chemicals

• Industrial Organic Chemicals

• Plant protective agent production

• Alkali’s & Chlorine

• Detergent production

• Water treatment

• Bromine Production

• Sulfur recovery

• Nitrogenous & Phosphorus Fertilizers

• Food Processing

• Pharmaceutical Preparation

• Sugar Industries

• Petroleum Refining